A 100% sustainable result: the French company ENVIE relies on FOR REC equipment to recover valuable materials contained in WEEE and creates a “recycling line” focused on employee safety.

A 100% sustainable result: the French company ENVIE relies on FOR REC equipment to recover valuable materials contained in WEEE and creates a “recycling line” focused on employee safety.

ENVIE deals with managing, reconditioning, disposing and recycling waste and electrical equipment while supporting social causes.

Their Strasbourg plant, in fact, is specifically designed to employ disadvantaged personnel, with slight disabilities or protected professional categories, always supported by professionals and specialized technicians. This collaboration has created an efficient and highly operational social activity, able to create added value and high quality output.

Envie has met the professionalism and skills of FOR REC and, thanks to this collaboration, the two companies created a project that has allowed the French firm to optimize its processes and create a recycling line that is both safe for employees and respectful of the surrounding environment.

The twofold aim of ENVIE was to: reduce environmental waste by putting reconditioned devices back on the market and recycle non-repairable material.

For this second project, the company was looking for a partner to support them in the creation of a recycling line, and FOR REC demonstrated that it was capable of facing the challenge.

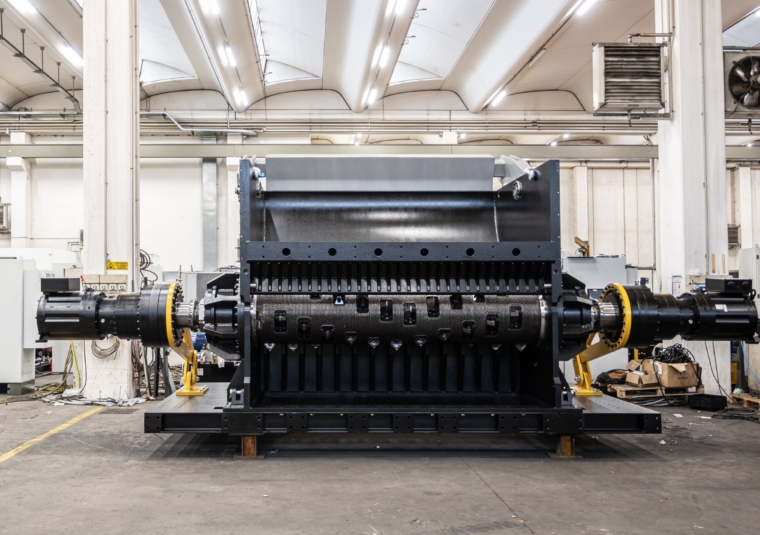

Thanks to custom machinery, FOR REC supported them in the transformation of waste into secondary raw material, with a dedicated line that safeguards the operators and helps them in the process of material selection, always ensuring maximum comfort and safety.

Thanks to its many years of experience and know-how in this sector, FOR REC has supported ENVIE in the realization of the recycling line, composed of a series of machineries that combine efficiency and comfort for the operators.

Thanks to the machinery implemented by FOR REC, the company has been able to focus on output quality, achieving an extremely high degree of cleanliness. All outgoing products are indeed free of impurities and 98% free of contamination.

Through this project, ENVIE has been able to optimize its efforts and is able to re-introduce more valuable components to the market.

Contact our technical staff and find out what solutions we can develop for your company!