Refrigerator recycling is one of the most delicate and complex industrial operations, but at the same time extremely important for environmental sustainability. Once refrigerators reach the end of their life cycle, it is crucial to treat them properly to avoid damage to the environment. Indeed, these appliances contain refrigerant gases, oils and materials that, if not handled correctly, can have a negative impact on the atmosphere. Proper separation and disposal of the solid components and gases contained in refrigerators is a key process to avoid the dispersion of harmful substances and to ensure the recovery of materials, such as metals and plastics, that can be reused for future processing.

FOR REC’s refrigerators recycling line: advanced technologies leading to optimal performance

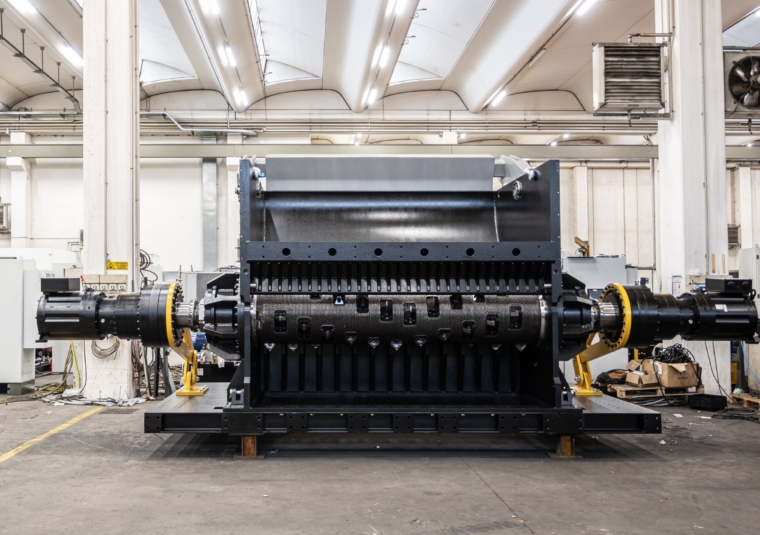

FOR REC’s refrigerators recycling line is a perfect example of innovation in industrial recycling. Using an integrated system of advanced machines, this line manages to process refrigerators with very high efficiency, separating and recovering materials accurately and safely. At the heart of the plant are high-capacity shredders that reduce refrigerators to fragments, ready for material separation.

Then, separation systems extract ferrous and nonferrous metals, plastics, copper, and aluminum, with great attention to minimizing waste.

The entire process is designed to ensure resource recovery and prevent harmful gases from being released into the environment; but the real strength of the FOR REC refrigerator recycling machines is the processing capacity of each component. In fact, these lines manage to separate all the different materials that make up the appliance, resulting in an extremely clean end product.

A plant which makes a big difference

To better understand how FOR REC’s refrigeration recycling plant works, watch our realization at work:

Constant evolution: the Boilers Recycling Plant.

Following the success of the refrigerator recycling plant, FOR REC has developed a similar line for the treatment of boilers. Because of the harmful gases inside these devices, in fact, boilers also require a dedicated treatment system.

FOR REC’s boiler recycling plant is designed to process up to 5.5 tons of boilers per hour, operating continuously, 24/7. The process includes pyramid shredding, separation of ferrous and nonferrous metals, material reduction, and specific gas treatment through advanced adsorption and cryocondensation technologies.

Innovation and sustainability: FOR REC’s philosophy for the development of new technologies

FOR REC is distinguished not only by the quality of its plants, but also by its continuous approach to research and development. Each plant is custom-designed to meet the specific needs of each customer, ensuring maximum performance and reduced consumption.

Through continuous technological innovation, FOR REC is able to handle large industrial recycling projects worldwide, making it a reliable partner for all treatment and recycling needs.