Boiler recycling is an increasingly important issue in industrial waste management and environmental sustainability.

In a world seeking more environmentally friendly and responsible solutions for the treatment of special waste, FOR REC has developed an innovative line for boiler recycling, capable of processing 5.5 tonnes of boilers per hour.

Why boiler recycling is crucial for the environment

Once decommissioned, these units contain significant amounts of recyclable materials such as aluminum, steel, and copper. If properly separated, these resources can be recovered and reused in new production cycles.

But that’s not all: boilers also contain ozone-depleting gases which, if not handled safely, can cause serious harm to the ecosystem. In particular, the polyurethane used as insulation can release hazardous gases such as CFCs, which are known for their damaging effects on the atmosphere.

Our project with DECONS SAS: an innovative solution

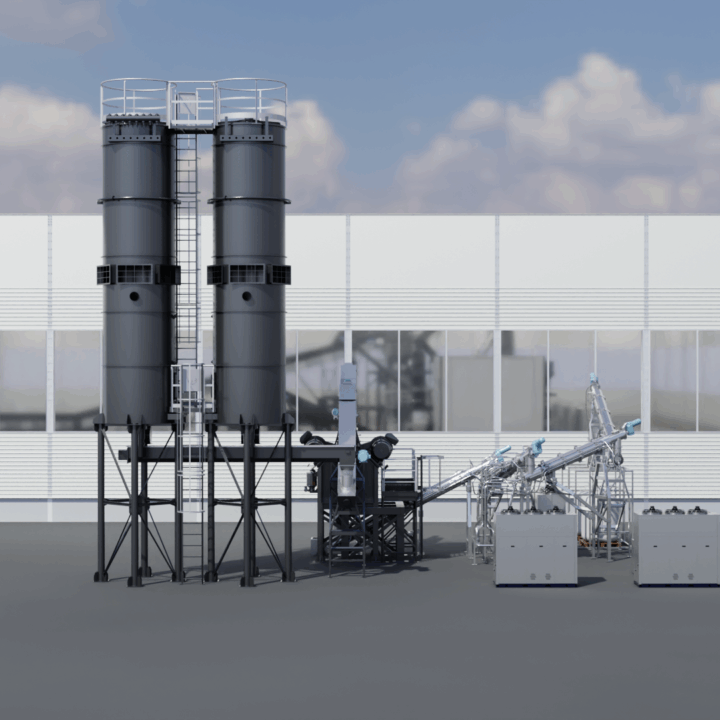

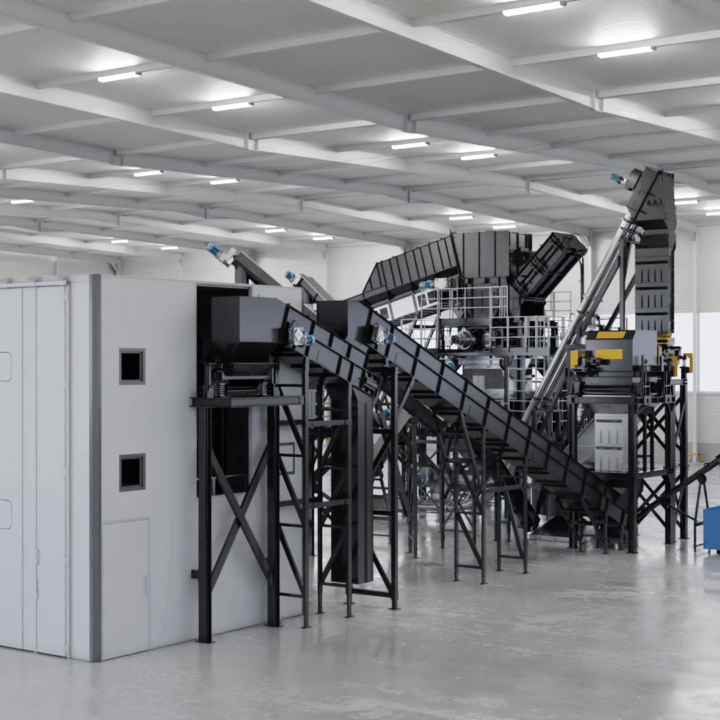

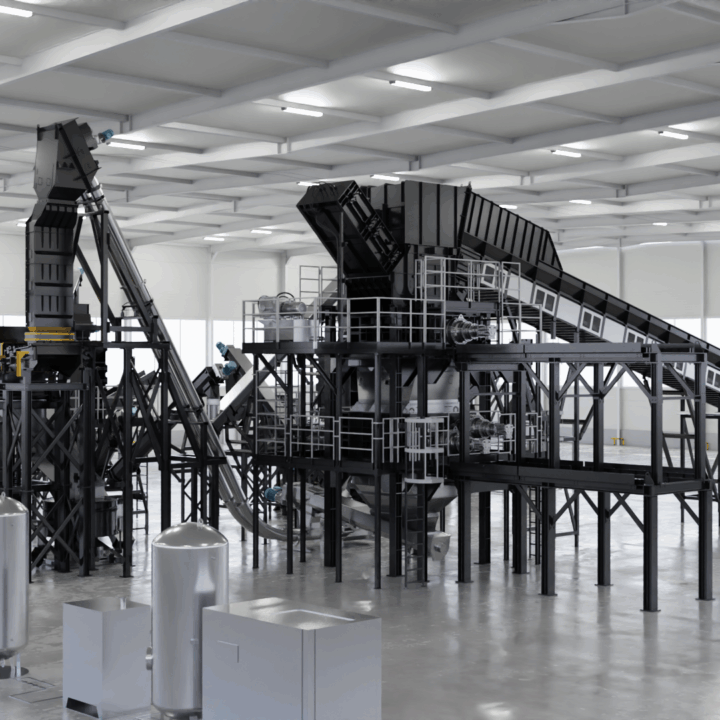

FOR REC’s new boiler recycling plant is the result of a collaboration with DECONS SAS, a well-known French company specialising in industrial metal recycling. The project stands out for its advanced technology, which allows for the separation of ferrous and non-ferrous metals, as well as the isolation of polyurethane present in boilers.

The plant has been designed to safely separate ozone-depleting gases through an activated carbon adsorption system, followed by a cryogenic condensation phase that converts them into liquid form for safe disposal.

The line is capable of processing 5.5 tonnes of boilers per hour, operating 24 hours a day, 7 days a week. This is a significant achievement that demonstrates the plant’s effectiveness in addressing the challenges of industrial recycling.

In addition, the plant is Weeelabex certified, an important recognition that guarantees compliance with European regulations on electronic waste, ensuring a transparent process that complies with international standards.